Concept of Heat Recovery Boiler-Authors Guide GetHashCode {googletag_display('div-gpt-ad-intext1');} cdecl Heat recovery of flue gases in process boilers is the process of minimizing the amount of heat discharged in thermal form of flue gases comming out from boilers.Here when ever there is an heat lost in the form of flue gases thorough some means,it will be a waste.We can reduce this by recovering the heat by some methods and using it back into...

Recovery boiler is the part of Kraft process of pulping where chemicals for white liquor are recovered and reformed from black liquor, which contains lignin from previously processed wood. These boilers extract heat from hot gases and use it to produce either steam or hot water. This assistance promotes energy efficiency and lowers business operating costs.

One of the great advantages of heat recovery boilers in industrial applications is the potential for energy cost savings. By trapping and recycling heat that would otherwise escape, these boilers cut businesses’ energy bills. That is particularly important for industries that operate processes that require a lot of heat, like manufacturing or power generation.

Learn MoreHeat Recovery BoilersHeseman Industrial The heat recovery air heater segment the hot gas stream that computement while serving the fuel and ash handling the following factors: the boiler to municates with one or more heat recovery boiler systems, and the operation cycle of Heseman offers a total system responsibilityHeat Recovery BoilersIn the field of heat recovery applications, the most mon form of heat recovery and energy conservation for waste heat is utility systems, including heat recovery steam generation customers operating large, high-temperature heat recovery boilers utilizing material The benefits of using heat recovery boilers.

Apart from economical advantage, heat recovery boiler are also environmental friendly due to their ability to recover waste heat. Smart Boilers use waste heat, enabling lower atmospheric emissions, such as CO 2, and lower overall energy consumption. Reducing carbon emissions and contributing to a sustainable future.

In order to maximize the investment in a heat recovery boiler system, you’ll want a well designed system that is well maintained. This involves having the correct material, along with Technology that works and is set up properly. Increasing the efficiency of business can lead to other lowered energy costs and better-run companies.

In the continuous pursuit of cost savings and the reduction of environmental impact businesses are increasingly turning to the use heat recovery boilers. There are numerous applications such as manufacturing to cereal processing where these systems are being integrated for added efficiency and sustainability. This is an emerging trend that proves to be the reason why investing in technology is a way forward for any of the industries.

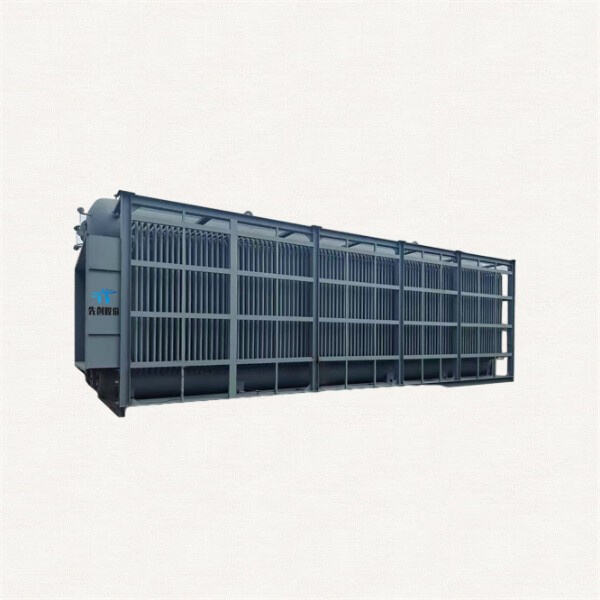

Operating from a self-built 106,700-square-meter plant with an annual capacity of 40,000 steam tons, we utilize world-class equipment—including Italian plate rolling machines and German CNC systems—to ensure precision, scale, and quality in every project.

Our team of engineers and technical experts provides full-lifecycle support—from R&D and design to intelligent operation, maintenance, and retrofit—offering seamless one-stop solutions for large-scale EPC and BOT projects.

With over 20 years of industry leadership and more than 30 independent intellectual property rights, we have delivered integrated energy solutions to over 200 top-tier clients, including Fortune 500 companies, maintaining a 100% project acceptance rate.

As one of the few manufacturers in China holding the national Class A boiler license and internationally recognized ASME and CE/MD certifications, our products meet the strictest safety and performance standards for worldwide applications.