Hot Oil Heaters Hot oil heaters are a type of industrial heater that uses oil to provide heat for industrial processes. Knowing how they work and why they matter can teach us something about how to keep them humming

Hot oil boilers heat oil to a high temperature and then use the heat to heat the space or area it flows through or to heat up a liquid. A fuel-oil burner heats the oil, which is stored in a special part of the heater, to about 140 degrees. From there, when the oil is hot enough, it’s transported through the pipes to where it’s needed.

There are a number of advantages to hot oil heat tracers over steam for industrial heating applications. One of the best parts is that they can heat areas fast. They also supply a steady amount of heat, which is crucial to many applications in industry. Meanwhile hot Steam boiler are easy to use and cycle, safe and efficient, can work under low pressure, energy saving, can be a good solution for your production through heating, although gas cast iron boilers are more efficient than hot oil heating.

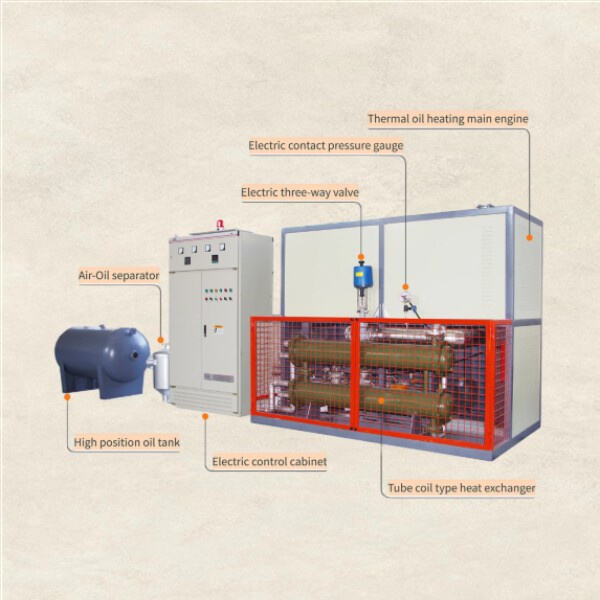

Key Components of Hot Oil Boilers There are a few key components that are important to control when using a hot oil boiler to produce energy. There are the burner, the heat exchanger, the pump and the control panel. These parts also need to be inspected and serviced frequently to help guarantee the smooth operation of the Thermal oil boiler. Maintenance tips include how to clean the burner, check for leaks in the pipes and replace any worn parts.

Hot oil boilers are another name for oil-fired boilers. Comparing a hot oil heating system to a steam heating system. Many of the same problems and failures that occur in a gas fired boiler occur in an oil fired boiler. Both these two types of boilers are common industrial boiler for heating, but hot heating Coal-fired Thermal Oil Boiler has some primary advantages. They warm up rooms faster and keep a more consistent temperature. Furthermore, hot oil boilers don’t require water and steam volume can be kept to a minimum which could pose a potential savings issue where water conservation is a concern.

Safety Precautions for operating your Hot Oil boiler Accidents do not happen, they are caused! Others include: keeping flammables away from the boiler, checking for leaks, and ensuring the burner is working properly. In an emergency, it’s crucial to know what to do and how to turn off the boiler properly.

With over 20 years of industry leadership and more than 30 independent intellectual property rights, we have delivered integrated energy solutions to over 200 top-tier clients, including Fortune 500 companies, maintaining a 100% project acceptance rate.

Our team of engineers and technical experts provides full-lifecycle support—from R&D and design to intelligent operation, maintenance, and retrofit—offering seamless one-stop solutions for large-scale EPC and BOT projects.

Operating from a self-built 106,700-square-meter plant with an annual capacity of 40,000 steam tons, we utilize world-class equipment—including Italian plate rolling machines and German CNC systems—to ensure precision, scale, and quality in every project.

As one of the few manufacturers in China holding the national Class A boiler license and internationally recognized ASME and CE/MD certifications, our products meet the strictest safety and performance standards for worldwide applications.